Slipper composite piston seals NPQ1 for Oil/gas applications

Piston Slipper NPQ1

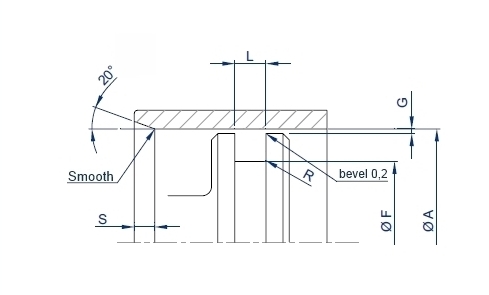

| class | A cylinder bore range |

F groove diameter |

L groove width |

R | S min. |

G* | closed groove |

||||||

| suggested | available | max. radial gap | if >= | ||||||||||

| H8 | h9 | H12 | Bar 50 | 100 | 200 | 400 | |||||||

| N3 | 15 - 39.9 | 15 - 80 | A- 11.0 | 4,2 | 0,8 | 2,6 | 0,6 | 0,5 | 0,25 | 0,15 | 30 | ||

| N4 | 40 - 79.9 | 40 - 133 | A- 15,5 | 6,3 | 1 | 5,6 | 0,7 | 0,5 | 0,3 | 0,2 | 50 | ||

| N5 | 80 - 132.9 | 80 - 260 | A- 21.0 | 8,1 | 1,5 | 8,2 | 0,9 | 0,6 | 0,3 | 0,2 | 80 | ||

| N6 | 133 - 252.9 | 80 - 260 | A- 24,5 | 8,1 | 1,5 | 8,2 | 1 | 0,7 | 0,35 | 0,2 | 133 | ||

| N7 | 253 - 462.9 | 253 - 700 | A- 28,0 | 9,5 | 2 | 12 | 1 | 0,7 | 0,4 | 0,25 | 320 | ||

| N8 | 463 - 700 | 450 - 700 | A- 35.0 | 11.5 | 3 | 15 | 1,1 | 0,75 | 0,45 | 0,25 | 463 | ||

| G*=G1+G2+G3 | G1 = Max. initial clearence G2 = Clearence by elastic deformation of the components under pressure G3 = Clearence due to the forseen wear of the guiding elements |

||||||||||||

| Coding example | |

| profile code NPQ1 bore 100 housing class N5 materials: Neuflon 031 O-Ring NBR |

Slipper NPQ1 - 100 - N5 - N-031 - NBR |

assembly

| SLIPPER COMPOSITE SEALS ASSEMBLING INSTRUCTIONS |

ASSEMBLY ON PISTON IN CLOSED GROOVE AND IN OPEN GROOVE

| Assembly in closed groove can be carried out manually, however the use of the appropriate equipment guarantees the integrity of the slipper and time-saving insertion. Assembly in open groove is suggested for slippers exceeding the dimensions shown in dimensional table. Correctly carried out introduction blunting and the lubrication of the surfaces make assembly easier. For an easier assembling in closed groove the preheating of the Slipper in oil or water bath at 90-100°C is suggested. |

INSERTION AND RECALIBRATION EQUIPMENT FOR INSTALLATION IN CLOSED GROOVES ON THE PISTON

| The expander cone brings the Slipper to the diameter of the piston, or to the edge of the groove when other existing grooves must be passed over. The thruster expands sector by sector, or more simply, in single logitudinal cutting. Both the cone and thruster can be made in acetal resin (POM), polyester (PBTF) or polyamide (PA6) The prolonged extended permanence of the Slipper during installation could determine a permanent increase in diameter; therefore fast installation is advised. |

|

| Recalibration of the slipper may be opportune using a sleeve before insertion of the piston in the cylinder. The sleeve also allows the passing over of grooves and threads. |

INSTALLATION ON THE CYLYNDER IN CLOSED GROOVE

|

The Slipper seal can be introduced in the closed groove imposing a reniform deformation.

|

The mono-directional R type Slipper is |

Vuoi maggiori informazioni?

Contatta il nostro laboratorio per soluzioni standard dal nostro catalogo e per prodotti personalizzati.

finishes

| SURFACE FINISH ACCORDING WITH FLUID | ||

| application | max Ra µm dynamic surface |

max Ra µm static surface |

| CRYOGENICS | 0,1 | 0,2 |

| FREON HELIUM HYDROGEN |

0,2 | 0,3 |

| AIR NITROGEN ARGON METHANE FUELS |

0.2 | 0.4 |

| WATER OIL |

0.3 - 04 | 0.6 |

| ROTARY SEALS | ||

| Shaft surface Ra 0.2 - 0.3 micron max. Rz 1.0 - 2.5 micron max. R max. < 4 micron |

Shaft hardness 55 HRC min. for pressure up to 5 bar 60 HRC min. for pressure > di 5 bar 60 HRC for speed > 4m/sec |

Surface treating deep 0.3 mm min. |

materials

Click compound's code to download the .PDF data sheet. Registration required.

| HD Slippers code |

Composition | Color | Approvals | ΔT °C | Description |

| N-020 | Virgin PTFE | white | FDA NORSOK |

-268 +260 | All pourpose, low friction coefficient, extrusion withstanding. |

| N-009 | Ptfe-oxides | blue | FDA | -268 +260 | All pourpose on soft surfaces |

| N-031 | Ptfe-bronze | green-blue | -268 +260 | High wear resistance, hidraulic seals | |

| N-032 | Ptfe-carbon | black | -268 +260 | High wear resistance, pneumatic and hydraulic seals | |

| N-059 | Ptfe-carbographite | black | -268 +260 | High wear resistance, hydraulic and pneumatic seals, hard surfaces | |

| N-197 | Ptfe-carbographite | black | NORSOK | -268 +260 | High wear resistance, hydraulic and pneumatic seals |

| N-043 | Ptfe-graphite | black | FDA | -268 +260 | High wear resistance, low friction coefficient. |

| N-103 | Ptfe-carbon fibre | black | FDA | -268 +260 | High wear resistance, low friction coefficient, hard surfaces. |

| N-077 | Ptfe-glass fibre-MoS2 | gray | -268 +260 | Of general use, in lubricated applications, rotary seals | |

| N-060 | Ptfe-glass fibre | blue | FDA | -268 +260 | All pourpose on hard surfaces |

| N-067 | Ptfe-glass fibre | white | FDA NORSOK |

-268 +260 | High wear and creep resistance |

| N-102 | Ptfe-Liquid crystal polymer | beige | FDA - EU |

-268 +260 | Food & Pharma, soft surfaces |

| N-088 | Ptfe-poliimmide | yellow | -268 +260 | High wear resistance. Soft surfaces | |

| N-074 | PEHMW | white | FDA | -140 +80 | High wear and extrusion resistance |

| P95-A252 | Polyurethane | blue | FDA | -50 +105 | Extrusion and wear withstanding, low friction coefficient |

| P95-VI251 | Polyurethane | violet | FDA | -30 +115 | CIP (clean in place) fluids compatible |

| P95-R198 | Polyurethane | red | -30 +125 | Extrusion and wear withstanding, low friction coefficient, high temperatures | |

| P95-AR255 | Polyurethane | orange | -30 +135 | Extrusion and wear withstanding, low friction coefficient, higher temperatures | |

| P95-G253 | Polyurethane MoS | gray | -30 +105 | Extrusion and wear withstanding, lower friction coefficient |

| CHOOSING Neuflon-ptfe compound ACCORDING WITH FLUID AND SURFACE | |||||

| SURFACES | |||||

| Steel HEC>=30-45 Temp. Mart. Inox Steel Cast Iron HRB<=200 Steel HRC>=45 Cast Iron HRB>200 |

Galvanic or chemical surfacing HV>=700 Chromium Bronze |

Bronze Brass |

Treated Aluminium | Aust. Inox Steel Glass |

|

| FLUIDS | NEUFLON-ptfe compounds (standard in bold) | ||||

| Hydraulic oil Transmission oil Fire resistant syntetic hydraulic oil |

N-031 N-032 N-060 N-077 P95-A112 |

N-031 N-032 N-060 N-077 P95-A112 |

N-009 N-043 N-032 P95-A112 |

N-032 N-074 P95-A112 |

N-009 N-032 N-074 P95-A112 |

| Water and oil/water emulsions | N-032 N-060 N-077 N-074 |

N-032 N-060 N-077 N-074 |

N-009 N-043 N-074 |

N-032 N-074 |

N-009 N-032 N-074 |

| Drugs and food | N-009 N-102 N-020 N-043 N-060 N-074 N-088 P95-B113 |

N-009 N-074 P95-B113 |

N-102 N-009 P95-B113 |

N-009 N-074 P95-B113 |

N-009 N-074 P95-B113 |

| Air | N-032 N-031 N-043 N-074 P95-A112 |

N-032 N-043 P95-A112 |

N-032 N-009 N-043 N-074 P95-A112 |

N-032 N-074 P95-A112 |

N-032 N-009 N-043 N-074 P95-A112 |

| Steam | N-032 N-043 |

N-032 | N-009 N-032 N-043 |

N-032 N-009 N-043 |

|

| Acids and Bases | N-032 N-059 N-074 |

N-032 N-043 N-074 |

N-009 N-032 N-043 N-074 |

||

ELASTOMER ACCORDING WITH FLUID

| FLUID | ELASTOMER |

| HYDRAULIC OIL - TRANSMISSION OIL | NBR |

| FIRE RESISTANT SYNTETIC HYDRAULIC OIL | EPDM |

| WATER AND WATER/OIL EMULSIONS | NBR |

| FOOD AND DRUG | MVQ |

| AIR | NBR |

| STEAM | EPDM - FFKM |

| ACIDS AND BASES | FKM - FFKM |

availability

- To check the availability:

-choose profile and compound from the drop-down menu

-input the desired housing class

-input the desired diameter - Once obtained the availability, a request for quotation can be sent.