Rotary shaft seal Rotowiper NRC

OVERVIEW

Rotary shaft seal Rotowiper NRC for linear and/or slow rotating movements.

NRC ROTOWIPERS are made up of an element in NEUFLON-ptfe and an O-Ring which is the energyzing element.

Speed up to 120 rpm with a max. of 0.6 m/sec for the peripheral speed and 5m/sec for the linear movements

They are installed in the very same grooves of the NRC Wipers

|

APPLICATIONS Hydraulics, pneumatics, chemical and food processing equipmentsTemperature range -60 a + 250°C |

CHARACTERISTICS Minimum dimensionsClosed groove Very low couple Protected wiper lip Ample chemical resistance range |

|

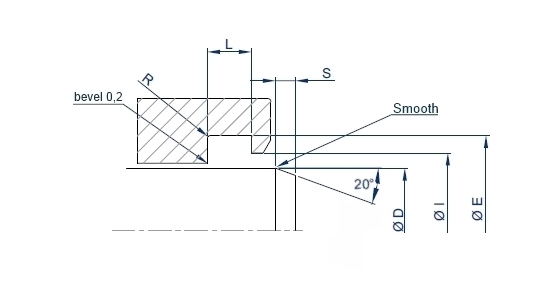

Housing |

D |

E |

I |

L |

R |

S |

In closed groove |

|

|

standard range |

special range |

H9 |

H12 |

H12 |

||||

|

W1 |

6 - 11,9 |

5 -100 |

D + 4,8 |

D + 1,5 |

3,7 |

0,3 |

1.4 |

20 |

|

W2 |

12 - 64,9 |

8 - 250 |

D + 6,8 |

D + 1,5 |

5,0 |

0,3 |

2.6 |

30 |

|

W3 |

65 - 250,9 |

10 - 450 |

D + 8,8 |

D + 1,5 |

6,0 |

0,4 |

3 |

40 |

|

W4 |

251 - 420,9 |

15 - 650 |

D + 12,2 |

D + 2,0 |

8,4 |

0,5 |

7 |

60 |

|

W5 |

421 - 650 |

120 - 1100 |

D + 16 |

D + 2,5 |

11,0 |

0,6 |

10 |

120 |

| Coding example | |

| profile code NRC rod 100 housing class W3 materials: Neuflon 031 O-Ring NBR |

Rotowiper NRC 100 W3 N-031 NBR |

materials

Click compound's code to download the .PDF data sheet (login requested)

| HD Slippers code |

Composition | Color | Approvals | ΔT °C | Description |

| N-009 | Ptfe-oxides | blue | -268 +260 | All pourpose on soft surfaces | |

| N-095 | Tfm | white | FDA | -268 +260 | Low creep, better strength. |

| N-031 | Ptfe-bronze | green-blue | -268 +260 | High wear resistance, hidraulic seals | |

| N-032 | Ptfe-carbon | black | -268 +260 | High wear resistance, pneumatic and hydraulic seals | |

| N-197 | Ptfe-carbographite | black | NORSOK | -268 +260 | High wear resistance, hydraulic and pneumatic seals |

| N-043 | Ptfe-graphite | black | FDA | -268 +260 | High wear resistance, low friction coefficient. |

| N-060 | Ptfe-glass fibre | blue | FDA | -268 +260 | All pourpose on hard surfaces |

| N-067 | Ptfe-glass fibre | white | FDA NORSOK |

-268 +260 | High wear and creep resistance |

| N-033 | Ptfe-glass fibre MoS2 | gray | FDA | -268 +260 | Fit for hard surfaces |

| N-103 | Ptfe-Carbon fibre | black | -268 +260 | Fit for hard surfaces | |

| N-102 | Ptfe-Liquid crystal polymer | beige | FDA - EU |

-268 +260 | Food & Pharma, fit for soft surfaces |

| N-088 | Ptfe-polyimide | yellow |

-268 +260 |

Fit for soft surfaces | |

| N-074 | PEHMW | white | FDA | -140 +80 | High wear and extrusion resistance |

| N-155 | PVDF | white | FDA | -30 +140 | High modulus |

| P95-A252 | Polyurethane | blue | FDA | -50 +105 | Extrusion and wear withstanding, low friction coefficient |

| P95-VI251 | Polyurethane | violet | FDA | -30 +115 | CIP (clean in place) fluids compatible |

| P95-R198 | Polyurethane | red | -30 +125 | Extrusion and wear withstanding, low friction coefficient, high temperatures | |

| P95-AR255 | Polyurethane | orange | -30 +135 | Extrusion and wear withstanding, low friction coefficient, higher temperatures | |

| P95-G253 | Polyurethane MoS | gray | -30 +105 | Extrusion and wear withstanding, lower friction coefficient |

| CHOOSING Neuflon-ptfe compound ACCORDING WITH FLUID AND SURFACE | |||||

| SURFACES | |||||

| Steel HEC>=30-45 Temp. Mart. Inox Steel Cast Iron HRB<=200 Steel HRC>=45 Cast Iron HRB>200 |

Galvanic or chemical surfacing HV>=700 Chromium Bronze |

Bronze Brass |

Treated Aluminium | Aust. Inox Steel Glass |

|

| FLUIDS | NEUFLON-ptfe compounds (standard in bold) | ||||

| Hydraulic oil Transmission oil Fire resistant syntetic hydraulic oil |

N-031 N-032 N-060 P95-A112 |

N-031 N-032 N-060 P95-A112 |

N-009 N-043 N-032 P95-A112 |

N-032 N-074 P95-A112 | N-009 N-032 N-074 P95-A112 |

| Water and oil/water emulsions | N-032 N-060 N-074 |

N-032 N-060 N-074 |

N-009 N-043 N-074 |

N-032 N-074 |

N-009 N-032 N-074 |

| Drugs and food | N-074 N-102 N-043 N-060 N-095 P95-B113 |

N-009 N-074 P95-B113 |

N-102 N-009 P95-B113 |

N-009 N-074 P95-B113 |

N-009 N-074 P95-B113 |

| Air | N-032 N-031 N-043 N-074 P95-A112 |

N-032 N-043 P95-A112 |

N-032 N-009 N-043 N-074 P95-A112 |

N-032 N-074 P95-A112 |

N-032 N-009 N-043 N-074 P95-A112 |

| Steam | N-032 N-043 |

N-032 | N-009 N-032 N-043 |

N-032 N-009 N-043 |

|

| Acids and Bases | N-032 N-074 |

N-032 N-043 N-074 |

N-009 N-032 N-043 N-074 |

||

Vuoi maggiori informazioni?

Contatta il nostro laboratorio per soluzioni standard dal nostro catalogo e per prodotti personalizzati.