|

ROTOLIP®

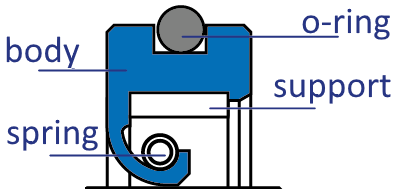

Rotary lip seals for rotating shaft. Integrated body and sealing lip in Neuflon-ptfe compound. Available with or without auxiliary O-Ring.

An inox support ring can be implemented according with the working conditions, it is supplied as standard when the shaft exeeds 100 mm.

|

Food, pharma and chemical applications.

Wide range of chemical resistance.

Suitable for lubricated or dry running conditions.

|

|

Rotoenerseal

spring energized rotary seal

single acting

medium pressure

moderate speed |

Criogenic applications

Food and pharma applications

Optional FDA approved silicone filling

Wide range of chemical resistance

|

|

Rotoslipper

double acting composite rotary seal

high pressure

low speed |

High pressure rotary seals.

Slow rotating movements, fast translational movements, combined roto-translational movements.

Max Pressure 800 bar.

Temperature range -60 a + 150°C

|

|

Rotowiper

single acting composite rotary seal

low pressure

low speed |

Closed groove

Very low torque

Protected wiping lip

Wide chemical resistance range

|

|

|

|

ROTOLIP®

Rotary lip seals for rotating shaft. Integrated body and sealing lip in Neuflon-ptfe compound. Available with or without auxiliary O-Ring.

The inox support ring can be implemented according with the working conditions, it is supplied as standard when the shaft exeeds 100 mm.

|

|

|

|

Rotolip® standard

Monodirectional rotary seal.

FDA applications

Available for any shaft from 6 to 350 mm

|

Operating conditions:

Temperature: -60 +250 °C

Speed: max 10m/sec if dry, up to 25m/sec with lubrication

Pressure: max 4 bar ( up to 10 bar with backup )

Versions R01 and R011 without support ring: shaft 100mm max.

Runout max 0,15mm

|

|

|

Rotolip® reinforced lip

Monodirectional rotary seal.

FDA applications.

Available for any shaft from 6 to 350 mm

|

Operating conditions:

Temperature: -60 +250 °C

Speed: max 5m/sec if dry, up to 15m/sec with lubrication

Pressure: max. 4 bar ( up to 10 bar with backup )

Versions R05 and R055 without support ring: shaft 100mm max.

Runout max 0,15mm

|

|

|

Rotolip® garter

Monodirectional rotary seal.

FDA applications

Available for any shaft from 6 to 350 mm

|

Operating conditions:

Temperature: -60 +250 °C

Speed: max 5m/sec if dry, up to 10 m/sec with lubrication

Pressure: max. 4 bar ( up to 10 bar with backup )

Versions R07 e R077 without support ring: shaft 100mm max.

Runout 0,30 mm max.

|

|

|

Rotolip® double lip

Monodirectional rotary seal.

Allows creating a reserve of lubricant between the sealing lips.

Available for any shaft from 20 to 350 mm

|

Operating conditions:

Temperature: -60 a +250 °C

Speed: max. 5 m/sec if dry, up to 15m/sec with lubrication

Pressure max. 4 bar

Runout 0,15mm max.

|

|

|

Rotolip® with opposite lips

Bidirectional rotary seal.

Available for any shaft from 20 to 350 mm

|

Operating conditions:

Temperature: -60 a +250°C

Speed: max. 5 m/sec if dry, up to 15 m/sec with lubrication

Pressure max. 2 bar

Dimensions on request

|

|

The technical-application data specified in catalogues, documentation and on this website are the result of more than forty years of experience and laboratory tests. The seal types suggested are the result of laboratory tests and thousands of field tests; however, the working conditions foreseen may not coincide with those of new applications and so lead to unexpected results. Therefore, HD Slippers Srl shall not be held responsible for the failure of sealing components that have not been tested under the actual working conditions. For new applications and the consequent manufacturing of specific seals, the user must conduct tests under the actual working conditions in order to approve the validity of the chosen solution. HD Slippers Srl guarantees the repeatability of the characteristics of seals tested and approved, except for subsequent modifications of applications and/or equipment and/or its components and/or processes, by the customer or a third part.

|