Enerwiper energized rod wipers made up of a wiping element in Neuflon-ptfe or PU or UHMW-PE, and an inox energizing spring.

Thespecial profile and the choice of materials make an extremely reliable component for completely preventing penetration of solid or liquid contaminants in the mechanical organs.

Wipers

Enerwiper rod wiper

OVERVIEW

Long term maintenance of the pre-load.

Closed groove

Low friction

Protected wiping lip

Great chemical resistance

APPLICATIONS

Hydraulics and pneumatics

Food and drugs (optional EU-FDA approved silicone filling) Optional MOCA certification

Linear speed up to 5 m/sec and slow rotating movements

T range -200 +260°C

Enerwiper

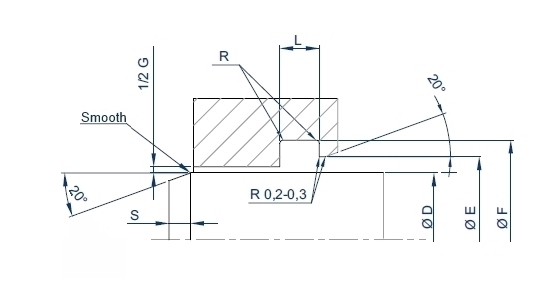

| Housing Class |

D rod |

F groove |

L axial width |

E ritegno |

R max. |

S min. |

| f7 | H9 | H12 | H12 | |||

| G | 3 - 20 | D + 2.9 | 2.4 | D + 1,9 | 0,3 | 2,5 |

| L | 15 - 240 | D + 4.5 | 3.6 | D + 3,1 | 0,4 | 2,5 |

| H | 25 - 400 | D + 6,2 | 4,8 | D + 4,2 | 0,6 | 3 |

| N | 45 - 650 | D + 9,4 | 7,1 | D + 6,5 | 0,8 | 5,5 |

| M | 80 - 1100 | D + 12,2 | 9,5 | D + 8,6 | 0,8 | 8,5 |

| Coding example | |

| housing class N rod 100 materials: jacket Neuflon 020 spring Aisi 302 |

Enerwiper N 100 N-020 302 |

assembly

|

Enerwiper spring energized wipers are suitable for assembling in closed groove starting from a minimum rod diameter according with dimensional class

|

||

|

Enerwiper rod wiper

|

dimensional class

|

Min. rod diameter

|

|

|

G L H N M R |

30 70 110 300 500 800 |

| |

||

materials

Click compound's code to download the .PDF data sheet

| HD Slippers code |

Composition | Color | Approvals | ΔT °C | Description |

| N-009 | Ptfe-oxides | blue | -268 +260 | All pourpose on soft surfaces | |

| N-095 | Tfm | white | FDA | -268 +260 | Low creep, better strength. |

| N-031 | Ptfe-bronze | green-blue | -268 +260 | High wear resistance, hidraulic seals | |

| N-032 | Ptfe-carbon | black | -268 +260 | High wear resistance, pneumatic and hydraulic seals | |

| N-197 | Ptfe-carbographite | black | NORSOK | -268 +260 | High wear resistance, hydraulic and pneumatic seals |

| N-043 | Ptfe-graphite | black | FDA | -268 +260 | High wear resistance, low friction coefficient. |

| N-060 | Ptfe-glass fibre | blue | FDA | -268 +260 | All pourpose on hard surfaces |

| N-067 | Ptfe-glass fibre | white | FDA NORSOK |

-268 +260 | High wear and creep resistance |

| N-033 | Ptfe-glass fibre MoS2 | gray | FDA | -268 +260 | Fit for hard surfaces |

| N-103 | Ptfe-Carbon fibre | black | -268 +260 | Fit for hard surfaces | |

| N-102 | Ptfe-Liquid crystal polymer | beige | FDA - EU |

-268 +260 | Food & Pharma, fit for soft surfaces |

| N-088 | Ptfe-polyimide | yellow |

-268 +260 |

Fit for soft surfaces | |

| N-074 | PEHMW | white | FDA | -140 +80 | High wear and extrusion resistance |

| N-155 | PVDF | white | FDA | -30 +140 | High modulus |

| P95-A252 | Polyurethane | blue | FDA | -50 +105 | Extrusion and wear withstanding, low friction coefficient |

| P95-VI251 | Polyurethane | violet | FDA | -30 +115 | CIP (clean in place) fluids compatible |

| P95-R198 | Polyurethane | red | -30 +125 | Extrusion and wear withstanding, low friction coefficient, high temperatures | |

| P95-AR255 | Polyurethane | orange | -30 +135 | Extrusion and wear withstanding, low friction coefficient, higher temperatures | |

| P95-G253 | Polyurethane MoS | gray | -30 +105 | Extrusion and wear withstanding, lower friction coefficient |

| CHOOSING Neuflon-ptfe compound ACCORDING WITH FLUID AND SURFACE | |||||

| SURFACES | |||||

| Steel HEC>=30-45 Temp. Mart. Inox Steel Cast Iron HRB<=200 Steel HRC>=45 Cast Iron HRB>200 |

Galvanic or chemical surfacing HV>=700 Chromium Bronze |

Bronze Brass |

Treated Aluminium | Aust. Inox Steel Glass |

|

| FLUIDS | NEUFLON-ptfe compounds (standard in bold) | ||||

| Hydraulic oil Transmission oil Fire resistant syntetic hydraulic oil |

N-031 N-032 N-060 P95-A112 |

N-031 N-032 N-060 P95-A112 |

N-009 N-043 N-032 P95-A112 |

N-032 N-074 P95-A112 | N-009 N-032 N-074 P95-A112 |

| Water and oil/water emulsions | N-032 N-060 N-074 |

N-032 N-060 N-074 |

N-009 N-043 N-074 |

N-032 N-074 |

N-009 N-032 N-074 |

| Drugs and food | N-074 N-102 N-043 N-060 N-095 P95-B113 |

N-009 N-074 P95-B113 |

N-102 N-009 P95-B113 |

N-009 N-074 P95-B113 |

N-009 N-074 P95-B113 |

| Air | N-032 N-031 N-043 N-074 P95-A112 |

N-032 N-043 P95-A112 |

N-032 N-009 N-043 N-074 P95-A112 |

N-032 N-074 P95-A112 |

N-032 N-009 N-043 N-074 P95-A112 |

| Steam | N-032 N-043 |

N-032 | N-009 N-032 N-043 |

N-032 N-009 N-043 |

|

| Acids and Bases | N-032 N-074 |

N-032 N-043 N-074 |

N-009 N-032 N-043 N-074 |

||