Spring Energized Rotary Seals Enerseal®,custom and standard dimensions available. Jacket in PTFE compound, PEEK, UHMW-PE. Jackets and electro-welded springs are designed and realized within the company, so that HD has the complete control of the production process. Spring are available in Aisi 301, Elgiloy, Hastelloy and NACE approved Inconel X750.

Optional filling with EU-FDA approved Silicone with MOCA certificate.

Enerseal® Spring Energized Seals

Energized Rotary Seals U

OVERVIEW

118

119

120

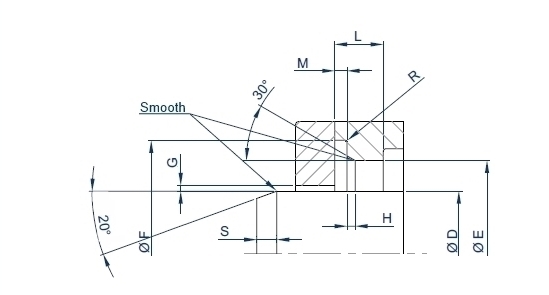

| housing class |

D dimensional range |

E groove diameter |

F flange groove diameter |

L groove width |

M flange groove width |

H chamfer |

S chamfer |

R max |

G max. radial gap |

| f7 | H9 | H12 | H12 | +0/-0.1 | |||||

| RUL | 5 - 240 | D+4.52 | D + 10.4 | 3.6 | 0.65 | 0.8 | 2.5 | 0.3 | 0.05 |

| RUH | 25 - 400 | D+6.15 | D + 13.8 | 4.8 | 0.75 | 1.35 | 3.0 | 0.4 | 0.08 |

| RUN | 45 - 650 | D+9.45 | D + 20.2 | 7.1 | 1 | 1.4 | 5.5 | 0.5 | 0.10 |

| RUM | 80 - 1100 | D+12.11 | D + 26.4 | 9.5 | 1.25 | 2.3 | 8.5 | 0.5 | 0.12 |

| Coding example | |

| housing class RUN profile code 118 rod 30 materials: jacket Neuflon 020 spring Aisi 301 |

Roto-Enerseal RUN 118 030 N-020 301 |

finishes

| SURFACE FINISH ACCORDING WITH FLUID | ||

| application | max Ra µm dynamic surface |

max Ra µm static surface |

| CRYOGENICS | 0,1 | 0,2 |

| FREON HELIUM HYDROGEN |

0,2 | 0,3 |

| AIR NITROGEN ARGON METHANE FUELS |

0.2 | 0.4 |

| WATER OIL |

0.3 - 04 | 0.6 |

| ROTARY SEALS | ||

| Shaft surface Ra 0.2 - 0.3 micron max. Rz 1.0 - 2.5 micron max. R max. < 4 micron |

Shaft hardness 55 HRC min. for pressure up to 5 bar 60 HRC min. for pressure > di 5 bar 60 HRC for speed > 4m/sec |

Surface treating deep 0.3 mm min. |

materials

Click compound's code to download the .PDF data sheet. Login required.

PTFE COMPOUNDS

| HD Slippers code |

Composition | Approvals | ΔT °C | Description |

| N-009 | Ptfe-oxides | -268 +260 | All pourpose on soft surfaces | |

| N-032 | Ptfe-carbon | -268 +260 | High wear resistance, pneumatic and hydraulic seals | |

| N-197 | Ptfe-carbographite | NORSOK | -268 +260 | High wear resistance, hydraulic and pneumatic seals |

| N-043 | Ptfe-graphite | FDA | -268 +260 | High wear resistance, low friction coefficient. |

| N-103 | Ptfe-carbon fibre | FDA | -268 +260 | High wear resistance, low friction coefficient, hard surfaces. |

| N-033 | Ptfe-glass fibre-MoS2 | -268 +260 | Of general use, in lubricated applications, rotary seals | |

| N-060 | Ptfe-glass fibre | FDA | -268 +260 | All pourpose on hard surfaces |

| N-067 | Ptfe-glass fibre | FDA NORSOK |

-268 +260 | High wear and creep resistance |

| N-102 | Ptfe-Liquid crystal polymer | FDA - EU |

-268 +260 | Food & Pharma on soft surfaces |

| N-088 | Ptfe-poliimmide | -268 +260 | High wear resistance. Soft surfaces | |

| N-074 | PEHMW | FDA | -140 +80 | High wear and extrusion resistance |

| CHOOSING Neuflon-ptfe compound ACCORDING WITH FLUID AND SURFACE | ||||

| SURFACES | ||||

| Steel HEC>=30-45 Temp. Mart. Inox Steel Cast Iron HRB<=200 Steel HRC>=45 Cast Iron HRB>200 |

Galvanic or chemical surfacing HV>=700 Chromium Bronze |

Treated Aluminium | Aust. Inox Steel Glass |

|

| FLUIDS | NEUFLON-ptfe compounds (standard in bold) | |||

| Hydraulic oil Transmission oil Fire resistant syntetic hydraulic oil |

N-031 N-032 N-060 N-077 P95-G114 |

N-031 N-032 N-060 N-077 P95-G114 |

N-032 N-074 P95-G114 | N-009 N-032 N-074 P95-G114 |

| Water and oil/water emulsions | N-032 N-060 N-077 N-074 |

N-032 N-060 N-077 N-074 |

N-032 N-074 |

N-009 N-032 N-074 |

| Drugs and food | N-102 N-043 N-060 N-074 N-088 P95-G114 |

N-009 N-074 P95-G114 |

N-009 N-074 P95-G114 |

N-009 N-074 P95-G114 |

| Air | N-032 N-031 N-043 N-074 P95-G114 |

N-032 N-043 P95-G114 |

N-032 N-074 P95-G114 |

N-032 N-009 N-043 N-074 P95-G114 |

| Steam | N-032 N-043 |

N-032 | N-032 N-009 N-043 |

|

| Acids and Bases |

N-032 |

N-032 N-043 N-074 |

N-009 N-032 N-043 N-074 |

|

availability

- To check the availability:

-choose profile and compound from the drop-down menu

-input the desired housing class

-input the desired diameter - Once obtained the availability, a request for quotation can be sent.